LD Electric Single girder Overhead Crane

Single beam bridge crane

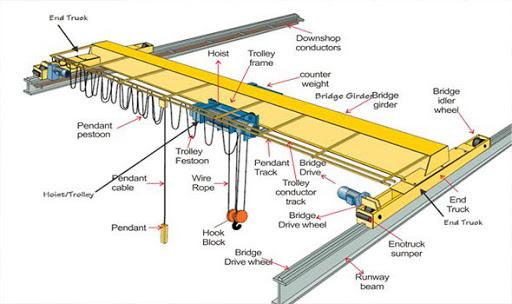

Single girder overhead crane usually refers to single girder bridge crane

The main beam of the single beam crane bridge is a simple section composed of I-steel or other section steel and plate steel. The lifting trolley is usually assembled with chain block, electric hoist or hoist as a lifting mechanism component. There are two kinds of operation: ground operation and air operation. The ground operation has two kinds of handle operation with line and remote control handle operation. The air operation refers to the operation of the cab.

There are two types of cabs, open and closed, which can be divided into left or right installation according to the actual situation.

The right side door and the end face of the entry direction allow users to choose single beam bridge cranes under different needs.

It is widely used in machinery manufacturing workshops, metallurgical workshops, petroleum, petrochemical, port, railway, civil aviation, power station, papermaking, building materials, electronics and other industries, warehouses, stockyards and so on. It has the advantages of compact overall dimensions, high and low building clearance, light self weight, small wheel pressure and so on. Compared with the single main beam gantry crane, the weight is larger and the cost is higher.

matters needing attention:

(1) Each crane shall be hung with the nameplate of rated lifting capacity in a visible place.

(2) During work, no one is allowed on the bridge or transported with a hook.

(3) Do not drive a crane without an operation license and after drinking.

(4) Concentrate during operation, and do not talk, smoke or do irrelevant things.

(5) The car should be clean; Equipment, tools, inflammables, and dangerous goods are not allowed to be placed randomly.

(6) Excessive use of cranes is not allowed.

(7) Lifting is not allowed under the following conditions: the binding is not firm; Excessive use of machine parts; The signal is unknown; Diagonal tension; Objects buried or frozen in the ground; There is someone on the hoisted object; Inflammables, explosives and dangerous goods without safety protection measures; Overfilled liquid objects; The steel wire rope does not meet the requirements for safe use; The lifting mechanism is faulty.

(8) When the crane is running on the line without obstacles, the hook or sling and the bottom surface of the lifted object should be more than 2m above the ground. If you cross an obstacle, you must cross it.

(9) For lifting objects less than 51% of the rated lifting capacity, two mechanisms are allowed to act at the same time; Lifting objects larger than 51% of the rated lifting capacity can only be operated by one mechanism.

(10) For bridge cranes with main and auxiliary hooks, do not raise or lower the main and auxiliary hooks at the same time.

(11) It is not allowed to weld or hammer on the lifted object and work under the object (if supported).

(12) After the power failure, and the sign of power failure operation is hung on the switch, the inspection or maintenance work can be carried out. If live work is required, safety measures must be taken to protect it, and special personnel shall be assigned to take care of it.

(13) Don’t throw things casually from the car.

(14) Limit switches and interlock protection devices should be checked frequently.

(15) It is not allowed to touch the limit switch as a parking method.

(16) When there is a problem with the lifting brake, it is not allowed to lift heavy objects.

(17) The hoisted object is not allowed to run over people or equipment.

(18) When welding a certain part of the crane, the ground wire shall be set, and it is not allowed to use the fuselage as the ground wire.

(19) When the hook is at the lower limit position, more than two safety loops shall be reserved on the drum.

(20) Cranes are not allowed to collide with each other, let alone use one crane to push another crane to work.

(21) when lifting heavy objects, liquid metals, explosives and dangerous goods, slowly lift them off the ground first to test the safety of the brake.

(22) the voltage of the lamp used for repair and inspection should be less than 36V.

(23) the electrical equipment shell of the bridge crane shall be grounded. If the trolley track is not welded on the main beam, measures should be taken to weld the ground wire. The grounding wire can be galvanized flat iron with a cross-sectional area greater than 75mm2 or 10mm2 bare copper wire or galvanized round steel with a cross-sectional area greater than 30mm2. The contact position of the cab or crane body should be more than two. The grounding resistance between each point on the crane and the neutral point of the power supply shall be less than 4 Ω

(24) safety technical inspection shall be carried out regularly, and pre inspection and pre repair work shall be done well.

| Capacity(t) | Span(m) | Lift height (m) |

Work class |

Lift speed (m/min) |

Track | Power rate (KW) |

| 5 | 7.5 | 6、9、12 | A5 | 0.8/5 | P24 | 7.75 |

| 10.5 | ||||||

| 13.5 | ||||||

| 16.5 | ||||||

| 19.5 | 8.15 | |||||

| 22.5 | ||||||

| 22.5 | P38 | |||||

| 10 | 7.5 | 6、9、12 | A5 | 0.8/5 | P38 | 12.1 |

| 10.5 | ||||||

| 13.5 | 12.8 | |||||

| 16.5 | ||||||

| 19.5 | ||||||

| 22.5 | ||||||

| 22.5 | P43 | |||||

| 15 | 7.5 | 6、9、12 | A5 | 0.66/4 | P38 | 12.8 |

| 10.5 | ||||||

| 13.5 | ||||||

| 16.5 | 13.6 | |||||

| 19.5 | ||||||

| 22.5 | ||||||

| 22.5 | P43 |